Blog

Composite Materials

The benefits of composite for engineering and marine application

A unique synthetic composite incorporating solid lubricants to ensure outstanding wear life. Our composite range has low friction no matter which grade you choose even without lubrication (Dry running)

Maintenance

No lubrication no maintenance or the cost of an automatic lubrication system. You achieve low friction and low wear.

No swell

With virtually no swelling in seawater and a very low thermal coefficient of expansion, the bearings provide dimensional stability in arctic and tropical seas. In addition, they do not corrode or promote corrosion of the housing and shaft and tolerate both edge loading and misalignment.

Strength

With 1/6 of the mass of steel and with a much higher strength-to-weight ratio it achieves excellent strength and elasticity.

Fitting

Achieved by bonding or freeze fitting,

Freeze fitting, using liquid nitrogen is a fast and efficient assembly method. The thermal properties of the material allow a good clearance between the bearing and housing when frozen and the material does not become brittle at cryogenic temperatures.

Bonding

Depending upon the design employed, in addition to traditional mechanical fixing. It can be bonded to both itself and metallic substrates.

If the assembly is to exceed a temperature of +60 °C to +70 °C/ +140 °F to +158 °F, then interference fit should be replaced with bonding.

Epoxies Acrylics Polyurethanes.

Press Fit

A hydraulic press or centre pull jacks are required if a bearing is to be press fitted. Installers should ensure that they have the equipment available to deliver adequate force to press the bearing fully into the housing.

The ease of fitting will vary depending on the finish of the housing. This should be considered when calculating the force required.

When press-fitting a bearing, it must be in line and square with the bore before the operation begins. An adequate chamfer on the housing will prevent the shaving of the bush.

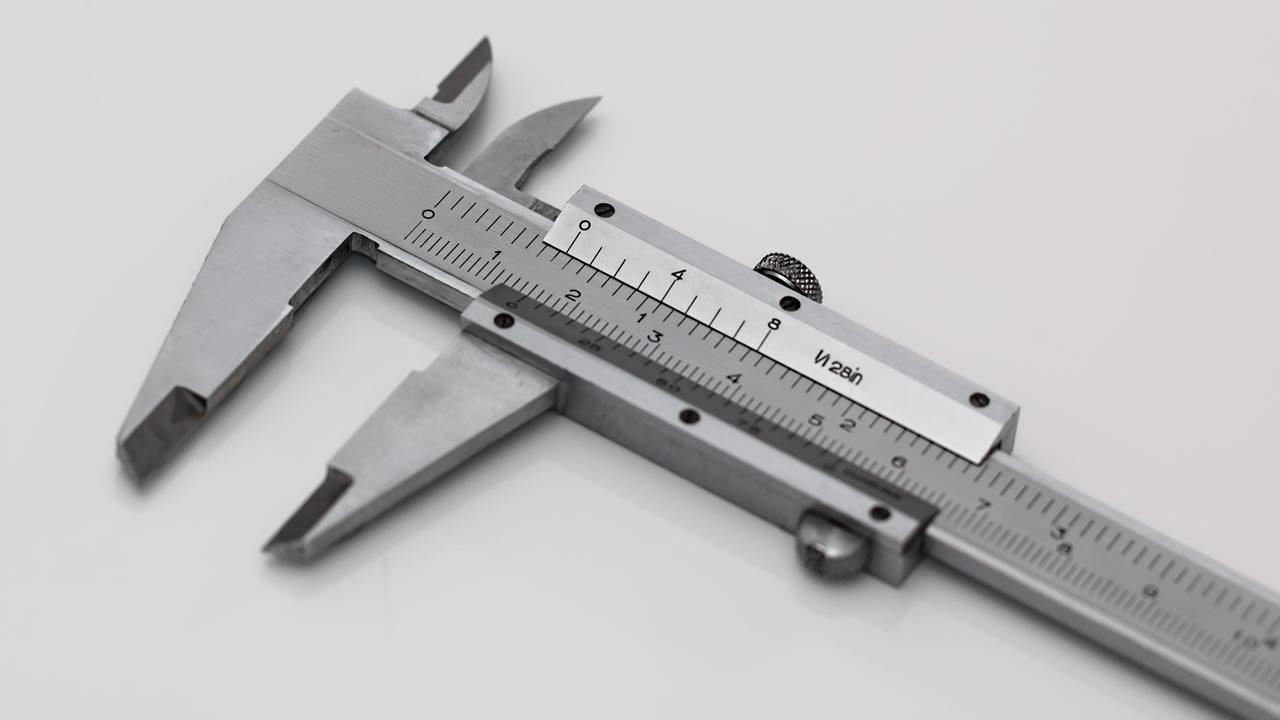

Machining

Composite materials can readily be machined using conventional machine shop techniques. As a general guide, methods used for brass, aluminium or lignum vitae will apply. It is preferable to use tungsten carbide turning tools with cutting speeds of 5 meters/ 20 feet per second. materials must be machined dry without the use of coolant.

Marine Grades

Our standard material incorporates a woven fabric reinforcement and solid lubricants within a thermosetting resin matrix. It can be used in conjunction with water and grease lubrication, running dry for limited periods.

Or specialized composite utilizes a specialized bearing surface to extend its dry running capabilities, reducing friction and wear rates. The material can also be used with grease and water lubrication.